September 4, 2017

Getting back to Joule over the holiday weekend, I returned to the aft deck to laminate the topspin over the new coring. I began by cleaning the cured thickened epoxy (squeeze out) from around the edges of the new core material, and then lightly sanded those surfaces. After vacuuming the surface and solvent washing it, I covered with a thin layer of plastic to create pattern for the 1708 biaxial cloth.

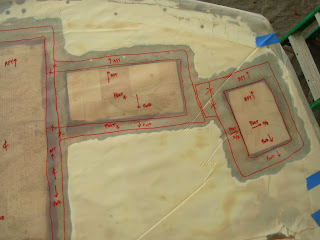

I traced a larger outer layer onto the plastic, and then a smaller inner layer.

The larger pattern would be laid on first, and then the smaller inner layer.

I cut the patterns from the plastic sheeting, working with the larger outer layer first. After cutting the larger layer, I cut the plastic pattern down to the smaller inner layer dimensions, and then cut those patterns from the 1708 biaxial cloth.

With all of the patterns prepared, I moved onto Joule to prepare the deck for lamination.

I wet out the new coring and then applied thickened epoxy (406 silica and 407 low-density) as a gap filler. After this prep work, I moved onto my work station on the ground and began to wet out the first (larger) layer of cloth. I laid the material down as I wet out each piece of cloth; and then proceeded in the same way for the second (smaller) layer.

With both layers on, I then covered the lamination with a clean layer of plastic and secured it to Joule.

I worked below to cover some fastener holes from the inside with tape - prepping for fill work. Since I ran out of solvent, I decided to call it for the day.

Total Time Today: 3.25 hrs

No comments:

Post a Comment